Do you want realistic plastic flowers but often see only cheap, fake-looking ones? Making high-quality plastic blooms is surprisingly difficult and requires specific machinery and skills.

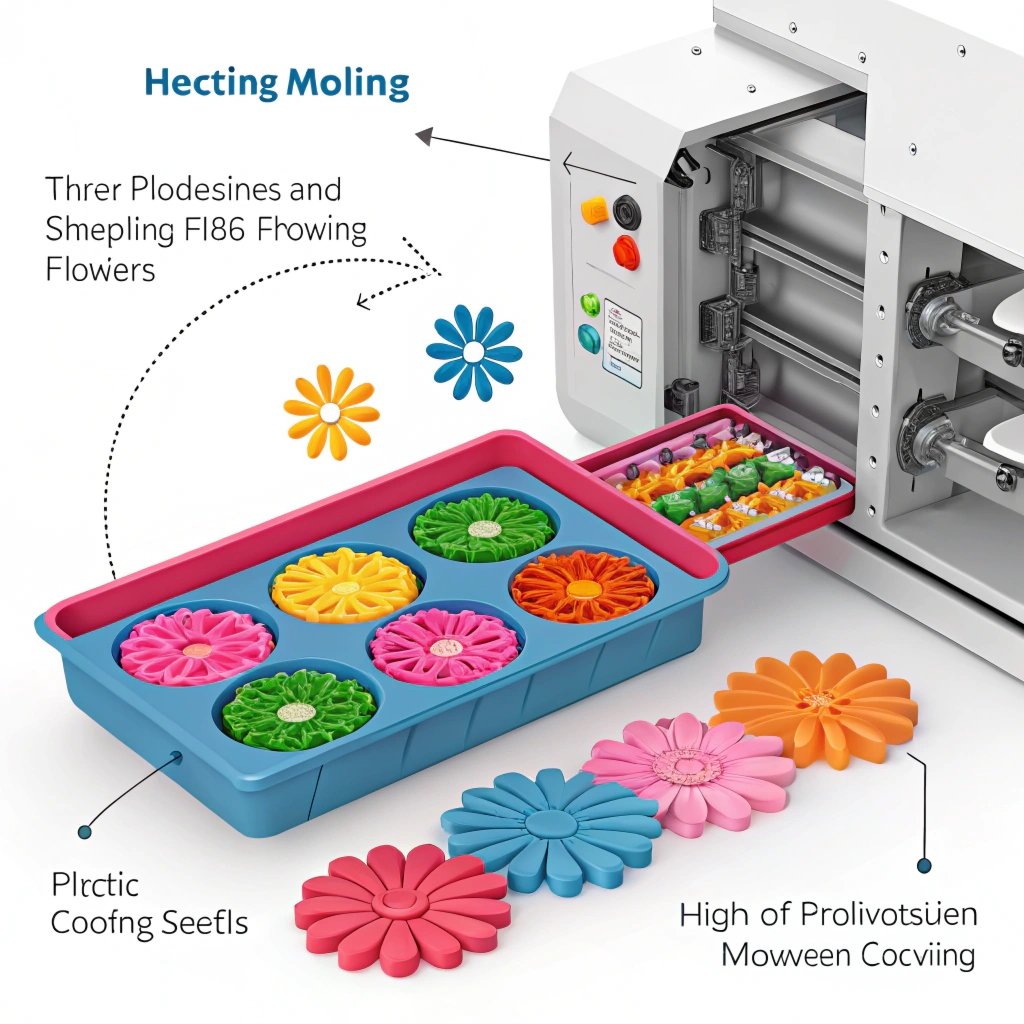

Injection molding machines1 create plastic flowers by melting plastic pellets2, injecting them into high-precision molds3, and carefully cooling them. The process involves three main steps: heating, shaping, and a critical cooling phase4 that determines the final shape and prevents shrinkage5.

I have learned a lot about manufacturing over the years running my business. It is not just about hats; it is about understanding how machines work. Let me explain the details of this process to you.

Why Can't Ordinary Machines Make Good Plastic Flowers?

Many factories try to make these flowers, but they often fail. The petals6 look thick and the edges are rough. Why does this happen so often?

Standard injection molding machines lack the necessary precision. High-quality plastic flowers require machines with tight tolerances7, typically found in manufacturers near coastal Fujian8 or Shanghai, rather than lower-precision options often seen in Hebei9.

You might think all machines are the same. This is not true. In my experience, the location of the machine manufacturer tells you a lot about the quality. Making a plastic flower is very hard. The petals6 are very thin. Sometimes they are as thin as a piece of paper. This means the mold must close perfectly. There cannot be any gaps.

If you use a machine made in Hebei9, you might have problems. I have seen these machines. They are cheaper, which is good for some things. But for flowers, they are not precise enough. They vibrate too much. When the machine shakes, the mold moves a tiny bit. This causes the hot plastic to leak out. We call this "flash10." It creates ugly lines on the flower petals6.

On the other hand, machines from the coastal Fujian8 area or around Shanghai are different. These factories focus on high precision. Their machines are stable. They hold the mold tight. This allows us to make petals6 that look real. We use similar high-quality equipment for our hat parts at Beauledo. Precision is the difference between a cheap toy and a quality product.

| Machine Origin | Precision Level | Typical Cost | Best Use Case |

|---|---|---|---|

| Hebei9 | Low to Medium | Low | Large, simple plastic parts (buckets, chairs) |

| Fujian/Shanghai | High | High | Intricate parts, thin-wall items, plastic flowers |

| German/Japanese | Very High | Very High | Medical devices, automotive electronics |

What Is the Most Difficult Step in the Process?

You might think melting the plastic is the hard part. But actually, keeping the shape after the plastic leaves the machine is much harder.

While the process has three steps, the cooling phase4 is the most difficult. If the cooling is uneven, the thin plastic petals6 warp or shrink, destroying the realistic look of the flower.

The process has three main steps. First, we heat the plastic. Second, we inject it. Third, we cool it down. The third step is where most factories lose money. Plastic shrinks when it gets cold. If a flower petal shrinks too much, it looks like a dead leaf. It twists in the wrong way.

I have a personal story about this. A few years ago, I worked with a client from Pakistan. It was my first time managing an order for plastic flowers for him. We did not set the cooling time correctly. The machine ran too fast. The flowers came out of the mold while they were still too hot. As they cooled on the table, they shrank. The petals6 curled up.

I was very worried. I thought the client would reject the whole order. It looked like a mistake. But when I showed him the sample, he smiled. He said, "This looks so real! It looks like a flower that is blooming." I was lucky that time. The mistake made the product look unique. But usually, shrinkage5 is bad. Now, we use precise temperature controllers11. We make sure the water inside the mold stays at the exact right temperature. This stops the plastic from moving after it leaves the mold.

| Process Step | Description | Main Challenge |

|---|---|---|

| Heating | Melting pellets into liquid | Preventing burning of the material |

| Injection | Pushing liquid into the mold | Filling every tiny corner of the petal |

| Cooling | Solidifying the shape | Controlling shrinkage5 and warping |

How Does Adding Color Affect the Production Quality?

We all love colorful flowers. But changing colors or adding color powder12 is a nightmare for the machine operator. It causes big problems.

Adding color powder12 requires stopping the machine and opening the mold. This interruption disrupts the internal temperature balance, leading to cooling issues and potential defects in the final batch of flowers.

Making a white flower is easy. Making a red or purple flower is hard. To add color, we have to put "color powder12" or masterbatch into the machine. This sounds simple. But it changes everything.

When we need to add powder, we often have to stop the machine. We might need to open the hopper. Sometimes we have to open the mold to clean it. When the machine stops, it starts to cool down. An injection molding machine is like a car engine. It runs best when it is hot and running fast. If you stop and start it, the temperature goes up and down.

This temperature change affects the cooling step I talked about earlier. If the mold gets cold because the machine stopped for five minutes, the next ten flowers will be bad. They will not fill the mold completely. Or they will have white streaks in the red color.

We have to be very careful. We try to mix the color very fast. We also use heaters to keep the mold warm while we add the powder. It takes a skilled worker13 to do this. If the worker is slow, we waste a lot of plastic. This is why colored plastic flowers are often more expensive to make than plain ones. It is not just the cost of the color. It is the cost of the time and the waste.

| Action | Impact on Machine | Result on Product |

|---|---|---|

| Stopping Machine | Temperature drops inside the barrel | Inconsistent melting |

| Opening Mold | Mold surface cools down | Surface defects, rough skin |

| Adding Powder | Changes chemical mix slightly | Color streaks or weak spots |

Conclusion

Making plastic flowers requires high-precision machines, strict cooling control, and skilled handling of color additives to ensure quality results.

Explore this link to understand the technology behind creating high-quality plastic flowers. ↩

Find out how plastic pellets are transformed into beautiful products. ↩

Learn about the importance of precision in mold-making for quality products. ↩

Discover why controlling the cooling phase is essential for product quality. ↩

Understand the factors that lead to shrinkage and how to mitigate them. ↩

Explore the techniques used to create lifelike plastic flower petals. ↩

Understand the significance of tight tolerances in producing high-quality items. ↩

Explore the manufacturing advantages of this region for precision products. ↩

Learn about the differences in manufacturing quality between regions. ↩

Learn about flash and its impact on the aesthetics of molded products. ↩

Discover how precise temperature control enhances product quality. ↩

Learn about the challenges of adding color to plastic products. ↩

Find out what expertise is required to produce high-quality plastic products. ↩